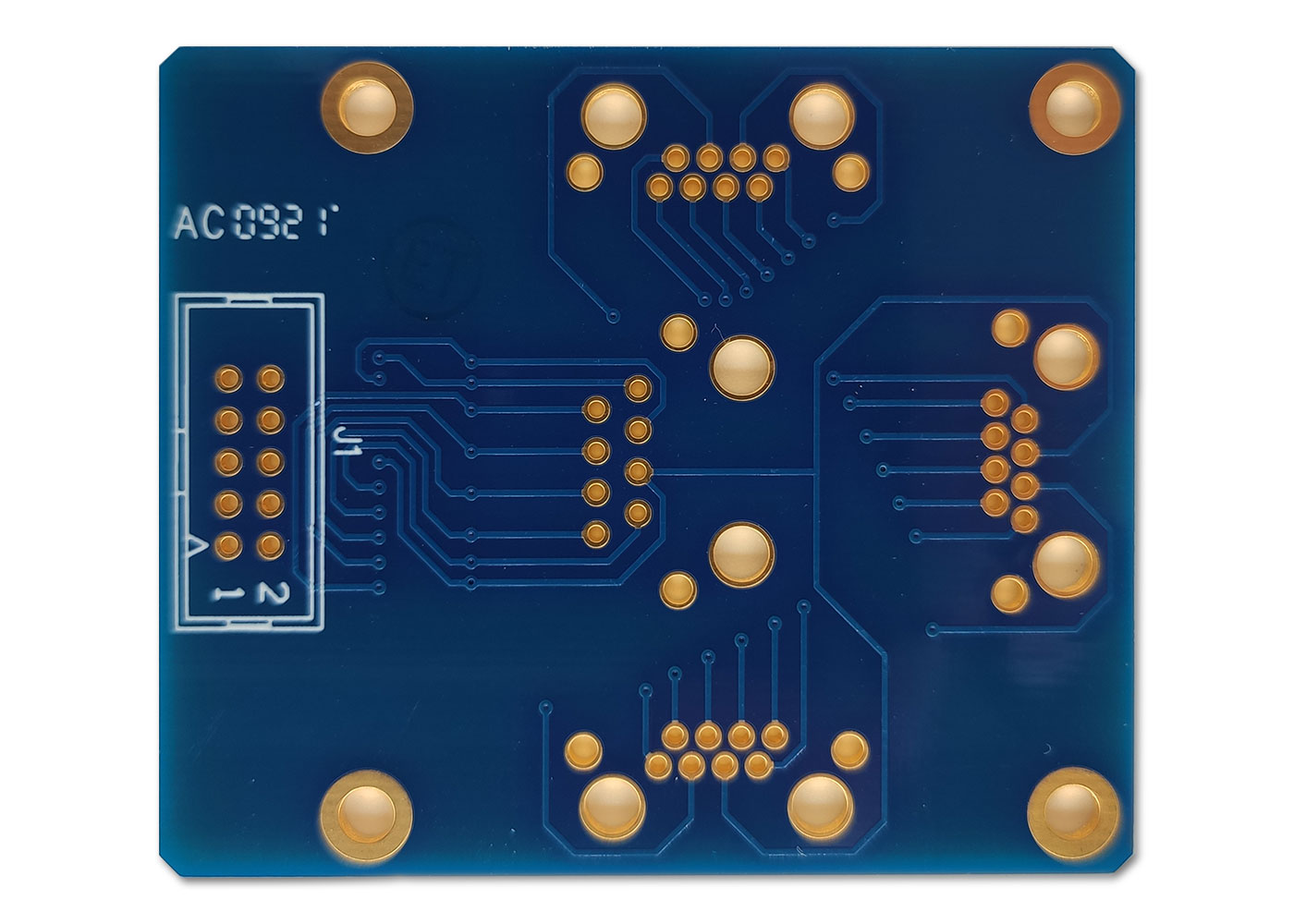

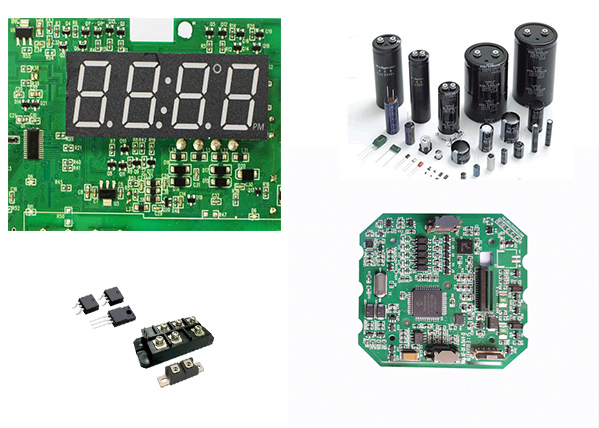

Abin da muke magana akai shine " FR-4 Fiber Class Material PCB Board "sunan lamba ne don darajar kayan da ke tsayayya da wuta. Yana wakiltar ƙayyadaddun kayan aiki cewa kayan resin dole ne su iya kashe kansu bayan an ƙone su. Ba sunan abu ba ne, amma nau'in kayan abu ne. Material grade, don haka akwai nau'ikan kayan FR-4 da yawa da ake amfani da su a cikin allunan da'ira gabaɗaya a halin yanzu, amma yawancinsu an yi su ne da abin da ake kira Tera-Function epoxy resin da filler (Filler) da fiber gilashin kayan da aka haɗa.

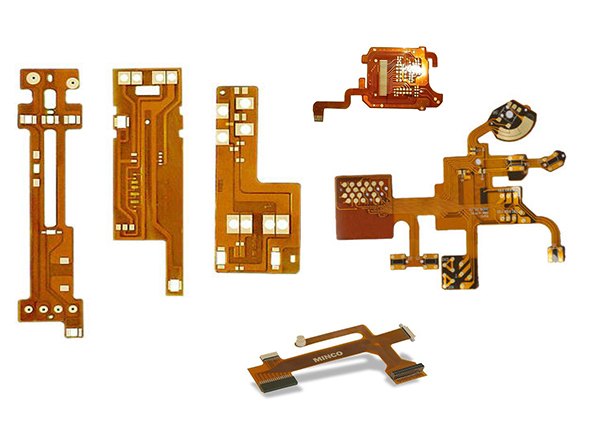

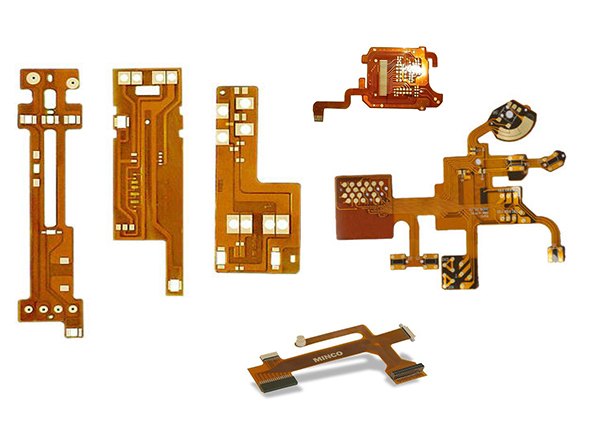

Allon kewayawa mai sassauƙa (Hukumar da'ira mai sassauƙa, gajeriyar FPC) kuma ana kiranta allon da'ira mai sassauƙa, ko allon da'ira mai sassauƙa.Ƙa'idar da'ira mai sassauƙa samfuri ne da aka ƙera kuma aka ƙera shi akan madaidaicin madauri ta hanyar bugu.  Akwai manyan nau'o'i biyu na bugu na allon da'ira: kayan da aka fi amfani da su da kuma kayan da aka fi amfani da su.Abubuwan da ake amfani da su na PCB sun bambanta don yadudduka daban-daban.Misali, allunan Layer 3 zuwa 4 suna buƙatar amfani da kayan da aka riga aka keɓance, kuma allon fuska biyu galibi suna amfani da kayan gilashi-epoxy. Lokacin zabar takardar, muna buƙatar la'akari da tasirin SMT

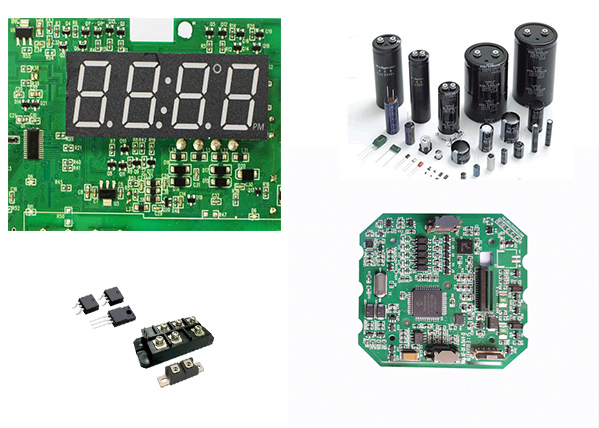

Akwai manyan nau'o'i biyu na bugu na allon da'ira: kayan da aka fi amfani da su da kuma kayan da aka fi amfani da su.Abubuwan da ake amfani da su na PCB sun bambanta don yadudduka daban-daban.Misali, allunan Layer 3 zuwa 4 suna buƙatar amfani da kayan da aka riga aka keɓance, kuma allon fuska biyu galibi suna amfani da kayan gilashi-epoxy. Lokacin zabar takardar, muna buƙatar la'akari da tasirin SMT A cikin tsarin hada-hadar lantarki mara gubar, saboda karuwar zafin jiki, matakin lanƙwasawa na allon da'irar da aka buga lokacin zafi yana ƙaruwa.Don haka, ana buƙatar amfani da allo tare da ƙaramin digiri na lanƙwasa a cikin SMT, kamar nau'in nau'in nau'in FR-4.

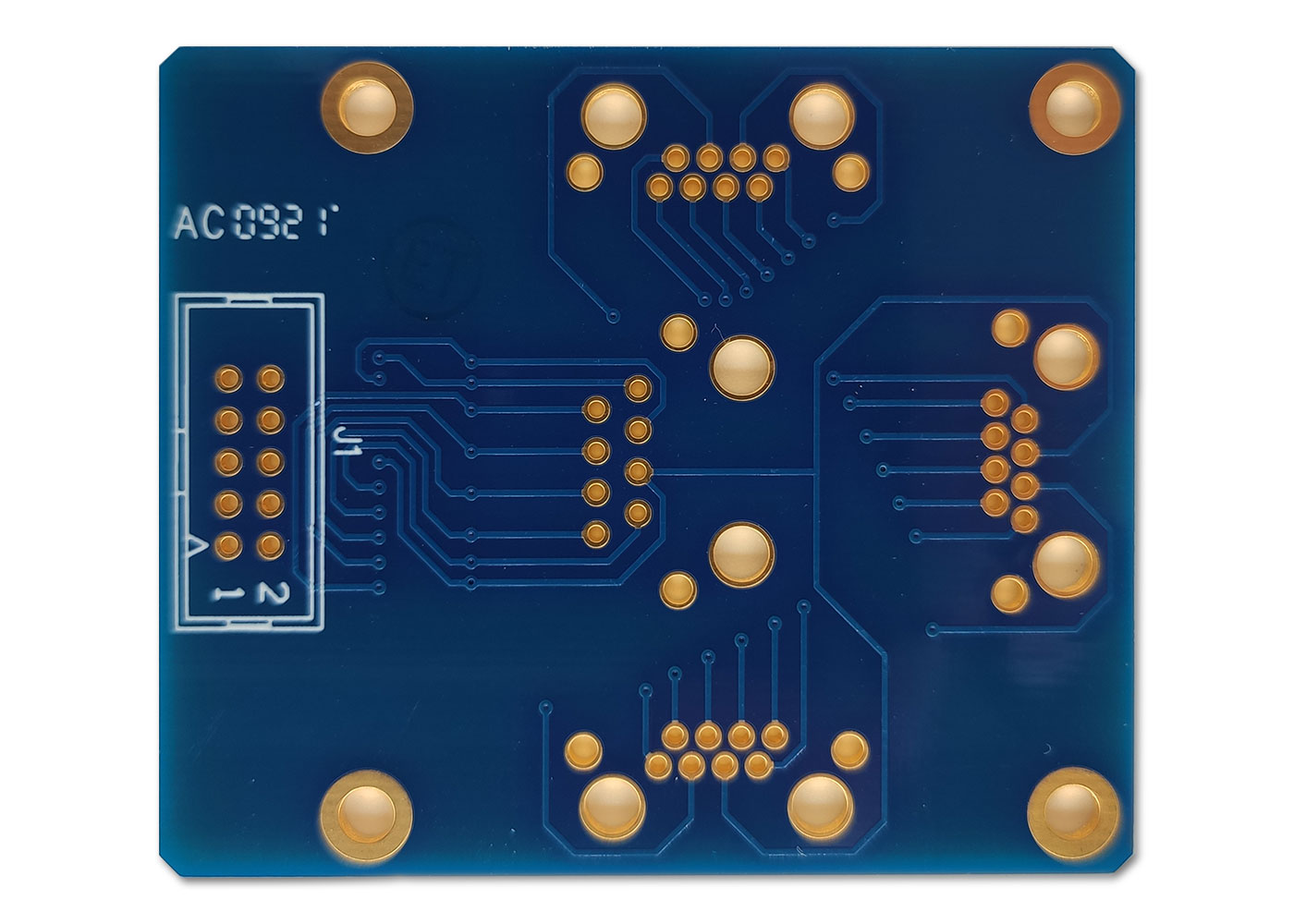

Tun da haɓakawa da damuwa na substrate bayan dumama yana rinjayar abubuwan da aka gyara, zai sa wutar lantarki ta kwasfa kuma ta rage amincin.Sabili da haka, ya kamata a kula da ƙayyadaddun ƙayyadaddun kayan haɓakawa lokacin zabar kayan, musamman lokacin da ɓangaren ya fi girma fiye da 3.2 × 1.6mm.PCB amfani a surface taron fasaha na bukatar high thermal watsin, m zafi juriya (150 ℃, 60min) da solderability (260 ℃, 10s), high jan karfe tsare manne ƙarfi (1.5 × 104Pa ko fiye) da lankwasawa ƙarfi (25 × 104Pa), high conductivity da ƙananan dielectric akai-akai, mai kyau punchability (daidai ± 0.02mm) da kuma dacewa da tsaftacewa jamiái, Bugu da kari, bayyanar da ake bukata don zama santsi da lebur, ba tare da warping, fasa, scars da tsatsa spots, da dai sauransu.  PCB kauri selection The kauri daga cikin buga kewaye allon ne 0.5mm, 0.7mm, 0.8mm, 1mm, 1.5mm, 1.6mm, (1.8mm), 2.7mm, (3.0mm), 3.2mm, 4.0mm, 6.4mm, wanda 0.7. mm da 1.5 Ana amfani da PCB tare da kauri na mm don ƙirar allon fuska biyu tare da yatsun zinariya, kuma 1.8mm da 3.0mm ba daidai ba ne masu girma dabam. Daga hangen nesa na samarwa, girman da aka buga kewaye hukumar kada ta kasance kasa da 250 × 200mm, da manufa size ne kullum (250 ~ 350mm) × (200×250mm).Don PCBs masu dogayen ɓangarorin ƙasa da 125mm ko faffadan ɓangarorin ƙasa da 100mm, mai sauƙi Amfani da hanyar jigsaw. The surface Dutsen fasaha ya kayyade yawan lankwasawa na substrate tare da kauri na 1.6mm a matsayin babba warpage ≤0.5mm da ƙananan warpage ≤1.2mm

PCB kauri selection The kauri daga cikin buga kewaye allon ne 0.5mm, 0.7mm, 0.8mm, 1mm, 1.5mm, 1.6mm, (1.8mm), 2.7mm, (3.0mm), 3.2mm, 4.0mm, 6.4mm, wanda 0.7. mm da 1.5 Ana amfani da PCB tare da kauri na mm don ƙirar allon fuska biyu tare da yatsun zinariya, kuma 1.8mm da 3.0mm ba daidai ba ne masu girma dabam. Daga hangen nesa na samarwa, girman da aka buga kewaye hukumar kada ta kasance kasa da 250 × 200mm, da manufa size ne kullum (250 ~ 350mm) × (200×250mm).Don PCBs masu dogayen ɓangarorin ƙasa da 125mm ko faffadan ɓangarorin ƙasa da 100mm, mai sauƙi Amfani da hanyar jigsaw. The surface Dutsen fasaha ya kayyade yawan lankwasawa na substrate tare da kauri na 1.6mm a matsayin babba warpage ≤0.5mm da ƙananan warpage ≤1.2mm

English en

English en