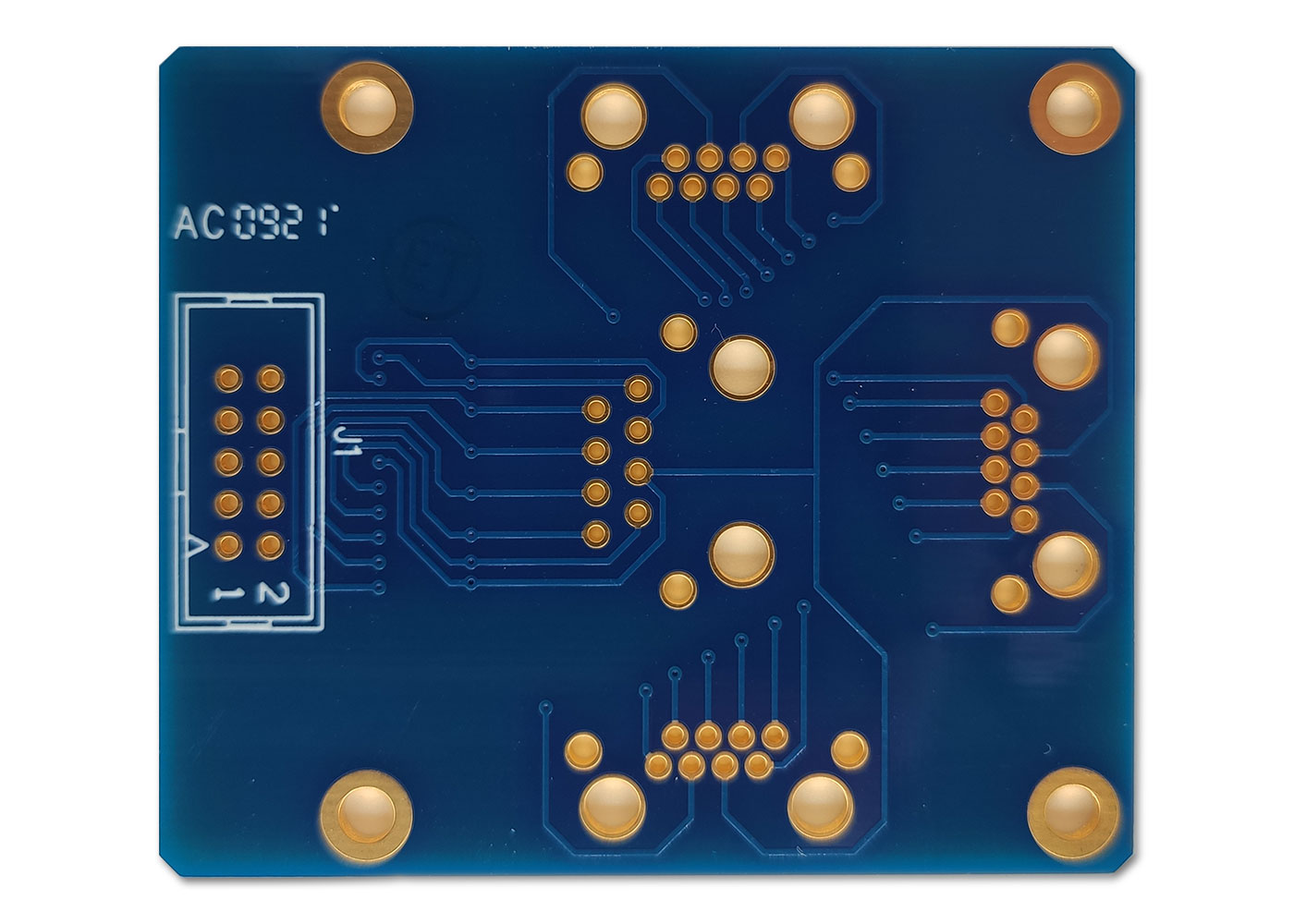

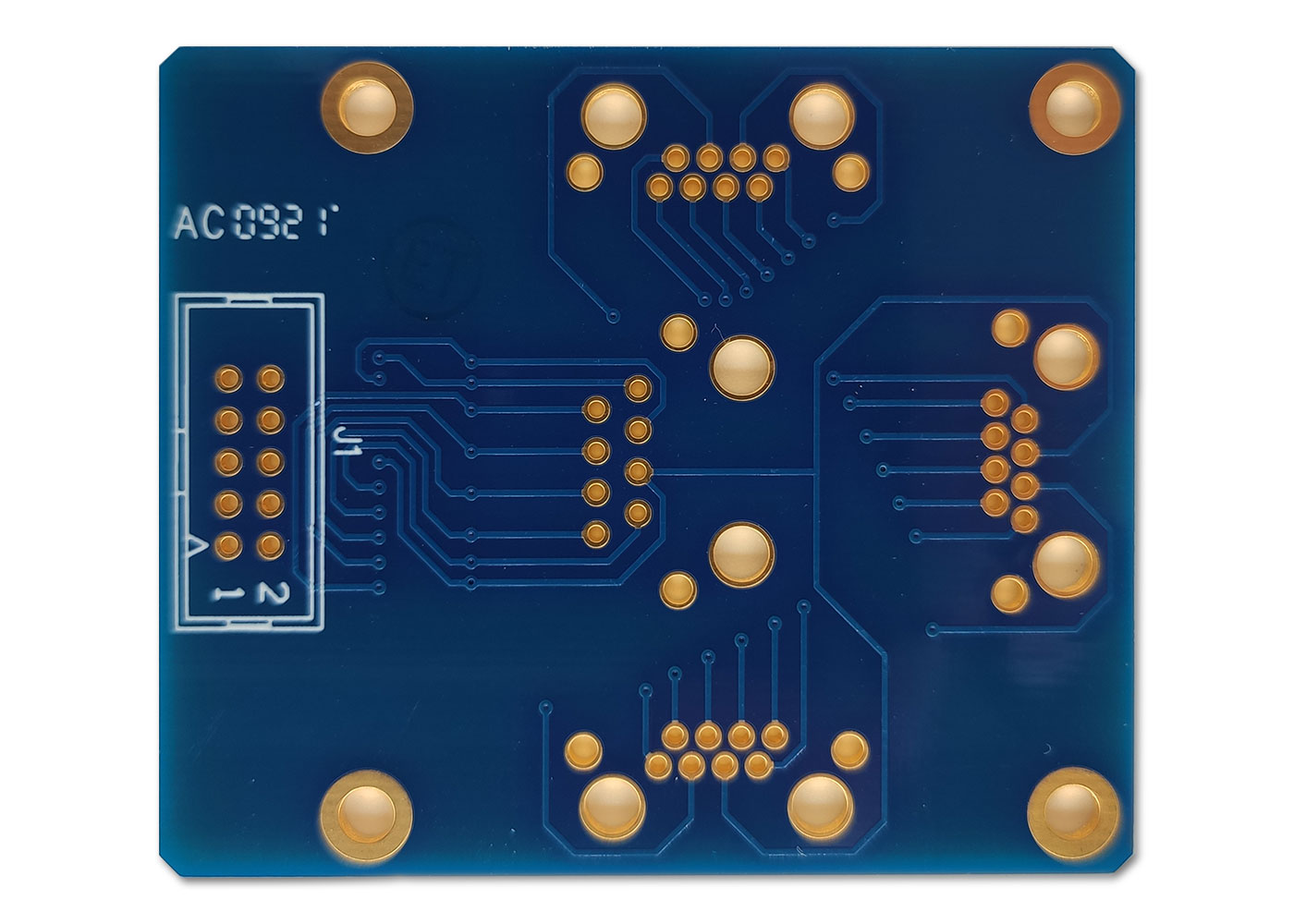

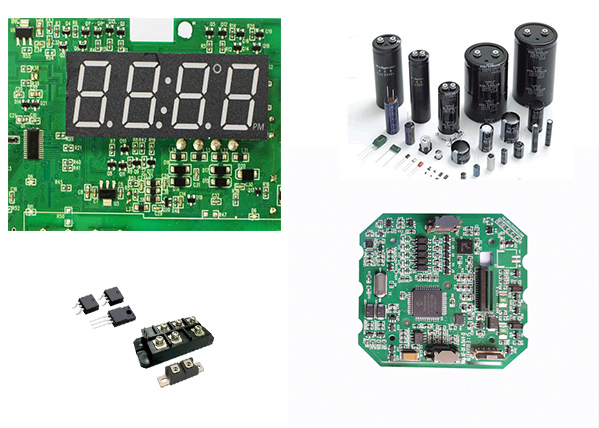

Seo re atisang ho bua ka sona ke " FR-4 Fiber Class Material PCB Board " ke lebitso la khoutu bakeng sa sehlopha sa lisebelisoa tse thibelang mollo. E emela tlhaloso ea thepa eo thepa ea resin e lokelang ho khona ho tima ka mor'a ho chesoa. Ha se lebitso la thepa, empa ke mofuta oa thepa. ho na le mefuta e mengata ea lisebelisoa tsa sehlopha sa FR-4 tse sebelisoang ka mapolanka a potoloho ka kakaretso hona joale, empa boholo ba tsona li entsoe ka seo ho thoeng ke Tera-Function epoxy resin plus filler (Filler) le khalase fiber Thepa e kopantsoeng e entsoeng.

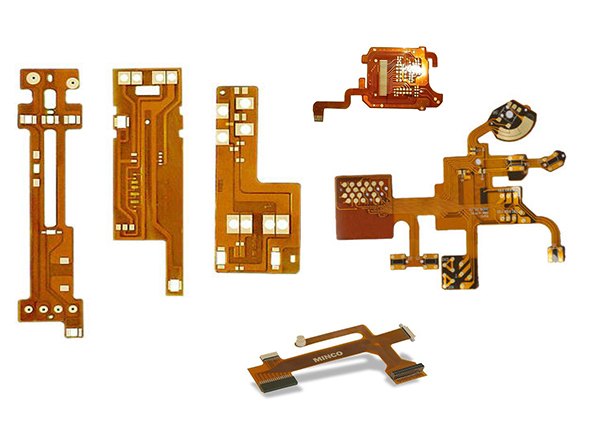

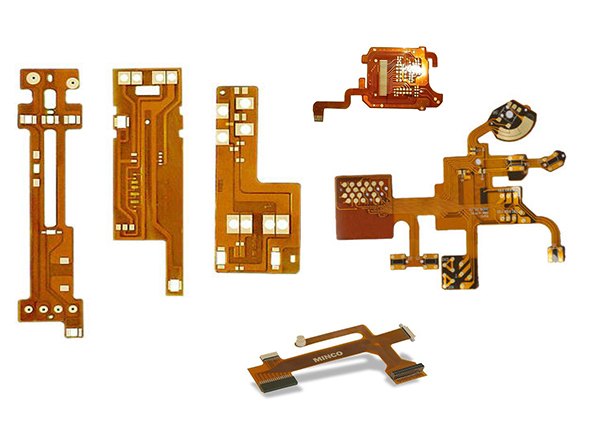

Flexible hatisitsoeng potoloho boto (Flexible Printed Circuit Board, e khutsufalitsoeng FPC) e boetse e bitsoa flexible printed circuit board, kapa flexible printed circuit board.The flexible printed circuit board ke sehlahisoa se entsoeng le ho etsoa ka substrate e feto-fetohang ka ho hatisa.  Ho na le mefuta e 'meli ea mantlha ea li-substrate tsa boto e hatisitsoeng: lisebelisoa tsa organic substrate le lisebelisoa tsa inorganic substrate, le lisebelisoa tsa organic substrate ke tsona tse sebelisoang haholo.Li-substrates tsa PCB tse sebelisoang li fapane bakeng sa lihlopha tse fapaneng.Ka mohlala, liboto tse 3 ho isa ho tse 4 li hloka ho sebelisa lisebelisoa tse entsoeng pele, 'me mapolanka a mahlakoreng a mabeli a sebelisa lisebelisoa tsa khalase-epoxy. Ha re khetha lakane, re hloka ho nahana ka phello ea SMT

Ho na le mefuta e 'meli ea mantlha ea li-substrate tsa boto e hatisitsoeng: lisebelisoa tsa organic substrate le lisebelisoa tsa inorganic substrate, le lisebelisoa tsa organic substrate ke tsona tse sebelisoang haholo.Li-substrates tsa PCB tse sebelisoang li fapane bakeng sa lihlopha tse fapaneng.Ka mohlala, liboto tse 3 ho isa ho tse 4 li hloka ho sebelisa lisebelisoa tse entsoeng pele, 'me mapolanka a mahlakoreng a mabeli a sebelisa lisebelisoa tsa khalase-epoxy. Ha re khetha lakane, re hloka ho nahana ka phello ea SMT Ts'ebetsong ea kopano ea elektronike e se nang moetapele, ka lebaka la ho eketseha ha mocheso, tekanyo ea ho khumama ea boto ea potoloho e hatisitsoeng ha e futhumala e eketseha.Ka hona, ho hlokahala ho sebelisa boto e nang le tekanyo e nyane ea ho kobeha ho SMT, joalo ka mofuta oa FR-4 substrate.

Kaha khatello ea ho atolosoa le ho fokotseha ha substrate ka mor'a ho futhumatsa ho ama likarolo, ho tla etsa hore electrode e fokotsehe le ho fokotsa ho tšepahala.Ka hona, coefficient ea ho atolosa thepa e lokela ho lefshoa ha u khetha thepa, haholo-holo ha karolo e le kholo ho feta 3.2 × 1.6mm.PCB sebelisoa ka holim 'mahlale a kopano hloka phahameng mogote conductivity, babatsehang mocheso ho hanyetsa (150 ℃, 60min) le solderability (260 ℃, 10s), phahameng koporo foil adhesion matla (1.5 × 104Pa kapa ho feta) le ho koba matla (25 × 104Pa), conductivity e phahameng le e nyenyane ea dielectric kamehla, punchability e ntle (ho nepahala ± 0.02mm) le ho lumellana le lisebelisoa tsa ho hloekisa, ho phaella moo, ponahalo e hlokeha hore e be e boreleli le e bataletseng, ntle le ho phunya, ho phunyeha, maqeba le mafome a mafome, joalo-joalo.  Khetho ea botenya ba PCB Botenya ba boto ea potoloho e hatisitsoeng ke 0.5mm, 0.7mm, 0.8mm, 1mm, 1.5mm, 1.6mm, (1.8mm), 2.7mm, (3.0mm), 3.2mm, 4.0mm, 6.4mm, e leng 0.7mm mm le 1.5 PCB e nang le botenya ba mm e sebelisoa bakeng sa moralo oa mapolanka a mahlakoreng a mabeli a nang le menoana ea khauta, 'me 1.8mm le 3.0mm ke boholo bo sa tloaelehang. Ho latela pono ea tlhahiso, boholo ba boto ea potoloho e hatisitsoeng ha ea lokela ho ba tlase ho 250 × 200mm, mme boholo bo loketseng ka kakaretso ke (250 ~ 350mm) × (200 × 250mm).Bakeng sa li-PCB tse nang le mahlakore a malelele a ka tlase ho 125mm kapa mahlakore a bophara a ka tlase ho 100mm, ho bonolo Ho sebelisa mokhoa oa jigsaw. Theknoloji ea holim'a holim'a thaba e bolela palo e kobehang ea substrate e nang le botenya ba 1.6mm e le leqephe le ka holimo la ntoa ≤0.5mm le warpage e tlaase ≤1.2mm

Khetho ea botenya ba PCB Botenya ba boto ea potoloho e hatisitsoeng ke 0.5mm, 0.7mm, 0.8mm, 1mm, 1.5mm, 1.6mm, (1.8mm), 2.7mm, (3.0mm), 3.2mm, 4.0mm, 6.4mm, e leng 0.7mm mm le 1.5 PCB e nang le botenya ba mm e sebelisoa bakeng sa moralo oa mapolanka a mahlakoreng a mabeli a nang le menoana ea khauta, 'me 1.8mm le 3.0mm ke boholo bo sa tloaelehang. Ho latela pono ea tlhahiso, boholo ba boto ea potoloho e hatisitsoeng ha ea lokela ho ba tlase ho 250 × 200mm, mme boholo bo loketseng ka kakaretso ke (250 ~ 350mm) × (200 × 250mm).Bakeng sa li-PCB tse nang le mahlakore a malelele a ka tlase ho 125mm kapa mahlakore a bophara a ka tlase ho 100mm, ho bonolo Ho sebelisa mokhoa oa jigsaw. Theknoloji ea holim'a holim'a thaba e bolela palo e kobehang ea substrate e nang le botenya ba 1.6mm e le leqephe le ka holimo la ntoa ≤0.5mm le warpage e tlaase ≤1.2mm

English en

English en