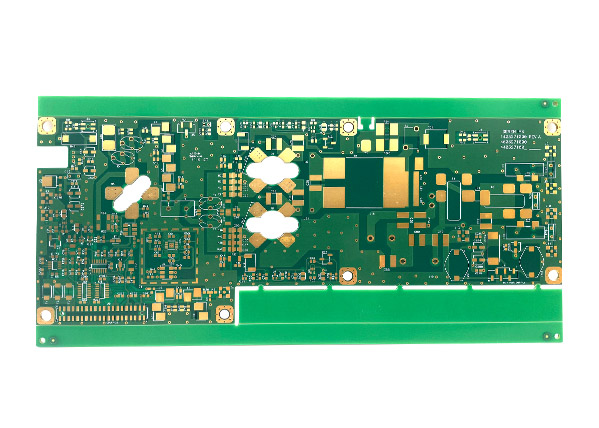

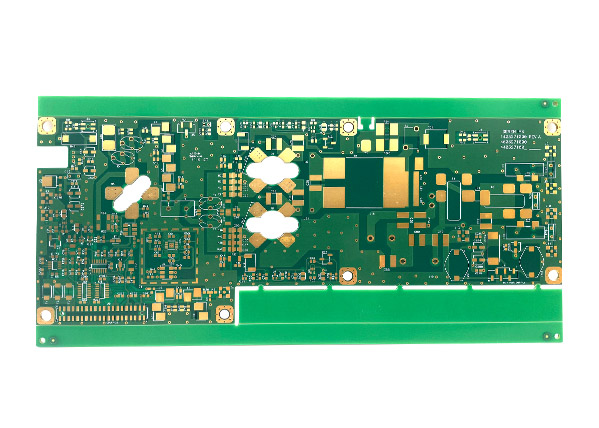

Litšobotsi tse 10 tsa PCB e tšepahalang haholo,

1. 20μm lesoba leboteng koporo botenya ba Boto ea potoloho e hatisitsoeng ,

Melemo: Ho tšepahala ho matlafalitsoeng, ho kenyelletsa le khanyetso e ntlafalitsoeng ea z-axis. Likotsi tsa ho se etse joalo: ho phunya masoba kapa ho tsoa, mathata a khokahanyo ea motlakase nakong ea kopano (karohano ea likarolo tse ka hare, ho robeha ha marako a lesoba), kapa ho hloleha ho ka bang teng tlas'a maemo a mojaro ha a sebelisoa.

2. Ha ho tokiso ea tjheseletsa kapa tokiso e bulehileng ya potoloho Molemo: Potoloho e phethahetseng e tiisa ho ts'epahala le polokeho, ha ho tlhokomelo, ha ho kotsi. Kotsi ea ho se etse sena: Haeba e lokisoa ka phoso, u tla theha potoloho e bulehileng botong.Leha e ka lokisoa 'hantle', ho na le kotsi ea ho hloleha tlas'a maemo a mojaro (vibration, joalo-joalo) e ka hlolehang ts'ebelisong ea 'nete. 3. Sebelisa CCL e tsebahalang ea machaba, Melemo: Ho tšepahala ho ntlafetseng, ho phela nako e telele le ts'ebetso e tsebahalang. Likotsi tsa ho se etse sena: Ho sebelisa lipampiri tsa boleng bo tlaase ho tla khutsufatsa haholo bophelo ba sehlahisoa, 'me ka nako e ts'oanang, thepa e mpe ea mochine oa lakane e bolela hore boto e ke ke ea sebetsa kamoo ho neng ho lebelletsoe tlas'a maemo a bokaneng, mohlala: katoloso e phahameng. thepa e ka lebisa ho delamination, potoloho e bulehileng le mathata a warping buckling, le thepa e fokolang ea motlakase e ka fella ka ts'ebetso e mpe ea impedance. Thepa ea fektheri ea ABIS PCB kaofela e tsoa ho bafani ba boto ba tsebahalang ba malapeng le ba kantle ho naha, 'me ba fihletse likamano tsa nako e telele tsa ts'ebelisano-mmoho le bafani ba thepa ho tsitsisa phepelo. 4. Sebelisa enke ea boleng bo holimo Melemo: Netefatsa boleng ba khatiso ea boto ea potoloho, ntlafatsa botšepehi ba ho hlahisa litšoantšo, le ho sireletsa potoloho. Kotsi ea ho se etse joalo: Li-inks tsa boleng bo tlaase li ka baka ho khomarela, ho hanyetsa flux le mathata a thata.Mathata ana kaofela a ka etsa hore mask a solder a tlohe botong 'me a qetelle a lebisa ho bola ha potoloho ea koporo.Thepa e fokolang ea ho kenya letsoho e ka baka li-circuits tse khutšoane ka lebaka la ts'ebetso ea motlakase ka phoso / arcing.

5. Feta litlhoko tsa bohloeki tsa litlhaloso tsa IPC Molemo: Bohloeki bo ntlafetseng ba PCB bo ntlafatsa ho tšepahala. Likotsi tsa ho se etse sena: Mesaletsa ka boto, solder build-up e ka hlahisa kotsi ho mask a solder, masala a ionic a ka baka kutu ea sebaka sa solder le kotsi ea tšilafalo e ka lebisang litabeng tse tšepahalang (manonyello a mabe a solder / mefokolo ea motlakase. ), 'me Qetellong e eketsa monyetla oa ho hloleha ha 'nete.

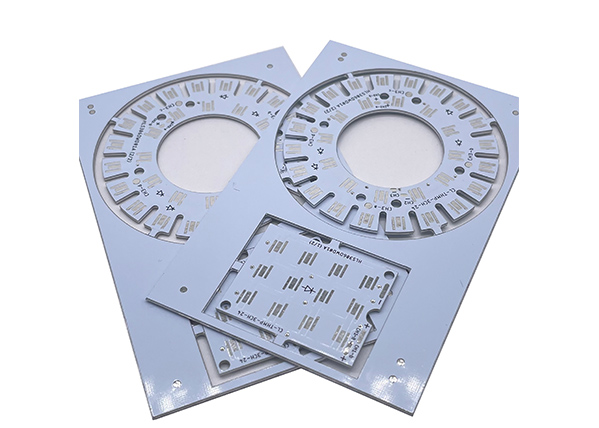

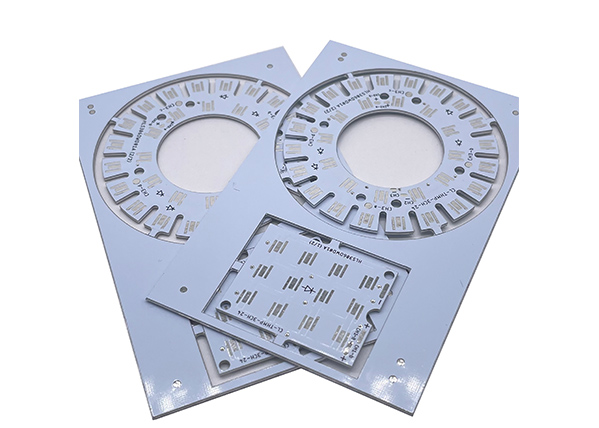

White solder mask Aluminium Circuit Board

6. Laola ka thata bophelo ba tšebeletso ea phekolo e 'ngoe le e' ngoe ea holim'a metsi Melemo: Ho rekisoa, ho tšepahala, le ho fokotsa kotsi ea ho kenella ha mongobo. Likotsi tsa ho se etse sena: Mathata a solderability a ka hlaha ka lebaka la liphetoho tsa metallographic karolong e ka holimo ea liboto tsa khale, 'me ho kenella ha mongobo ho ka baka delamination, likarolo tse ka hare le marako a lesoba nakong ea kopano le/kapa tšebeliso ea sebele Karohano (potoloho e bulehileng), joalo-joalo. mokhoa oa ho fafatsa ka holim'a thini e le mohlala, botenya ba ho fafatsa ka thini ke ≧1.5μm, 'me bophelo ba tšebeletso bo bolelele. 7. Sekoti sa plug ea boleng bo phahameng Molemo: Likoti tsa plug tsa boleng bo holimo fekthering ea PCB li tla fokotsa kotsi ea ho hloleha nakong ea kopano. Kotsi ea ho se etse sena: Masalla a lik'hemik'hale a tsoang ha ho qoelisoa ka khauta a ka lula ka har'a masoba a sa koaloang ka ho feletseng, 'me a baka mathata a kang ho qhibiliha.Ho phaella moo, ho ka 'na ha boela ha e-ba le lifaha tsa thini tse patiloeng ka mekoting.Nakong ea kopano kapa tšebeliso ea sebele, lifaha tsa thini li ka 'na tsa phatloha' me tsa baka potoloho e khutšoanyane. 8. Mamello ya CCL e fihlela ditlhoko tsa IPC 4101 ClassB/L Molemo: Taolo e tiileng ea botenya ba dielectric layer e fokotsa ho kheloha ts'ebetsong e lebelletsoeng ea motlakase. Kotsi ea ho se etse joalo: Ts'ebetso ea motlakase e kanna ea se fihlelle litlhoko tse boletsoeng, 'me likarolo tse tsoang sehlopheng se le seng li ka fapana haholo ka tlhahiso/ts'ebetso. 9. Laola ka thata ho mamellana ha libopeho, likoti le likarolo tse ling tsa mochine Molemo: Mamello e laoloang ka thata e ntlafatsa boleng ba sehlahisoa - ho lekana hantle, sebopeho le tšebetso. Likotsi tsa ho se etse sena: Mathata nakong ea kopano, joalo ka ho tsamaisana le ho nyallana (mathata a li-press-fit pins a fumanoa feela ha kopano e felile).Ho feta moo, ho kenya setsi ho ka ba bothata ka lebaka la ho kheloha ho eketsehileng.Ho ea ka litekanyetso tse phahameng tsa ho tšepahala, mamello ea boemo ba lesoba e ka tlase kapa e lekana le 0.075mm, mamello ea bophara ba lesoba ke PTH ± 0.075mm, 'me mamello ea sebopeho ke ± 0.13mm. 10. Botenya ba mask a solder bo lekaneng ka ho lekaneng Melemo: Ho ntlafala ha lisebelisoa tsa motlakase, ho fokotsa kotsi ea ho ebola kapa ho lahleheloa ke ho khomarela, ho eketseha ha khanyetso ho ts'oenyeho ea mechine - kae kapa kae moo e hlahang teng! Kotsi ea ho se etse joalo: Maske a tšesaane a solder a ka baka ho khomarela, ho hanyetsa flux le mathata a thata.Mathata ana kaofela a ka etsa hore mask a solder a tlohe botong 'me a qetelle a lebisa ho bola ha potoloho ea koporo.Lintho tse fokolang tsa ho kenya letsoho ka lebaka la mask a masesaane a solder, li ka baka lipotoloho tse khutšoane ka lebaka la ho khanna ka phoso / arcing.

Ba bang, ka kopo rfq, Mona!

English en

English en