HDI allo , babban haɗin haɗin gwiwa buga allon kewayawa

Allolin HDI ɗaya ne daga cikin fasahar haɓaka mafi sauri a cikin PCBs kuma yanzu ana samun su a ABIS Circuits Ltd.

Allolin HDI sun ƙunshi makafi da/ko binne ta hanyar mota, kuma yawanci suna ɗauke da microvias na 0.006 ko ƙarami diamita.Suna da girma mai girma fiye da allunan kewayawa na gargajiya.

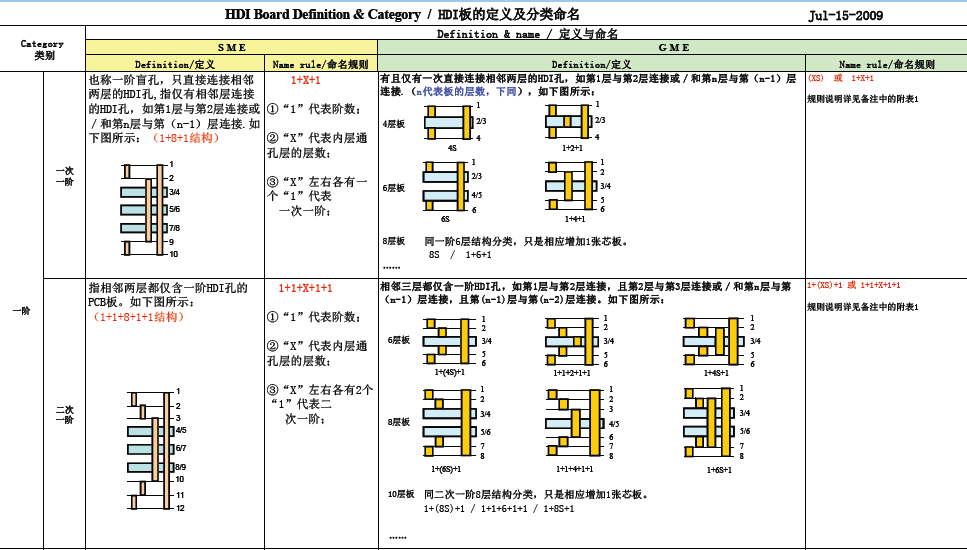

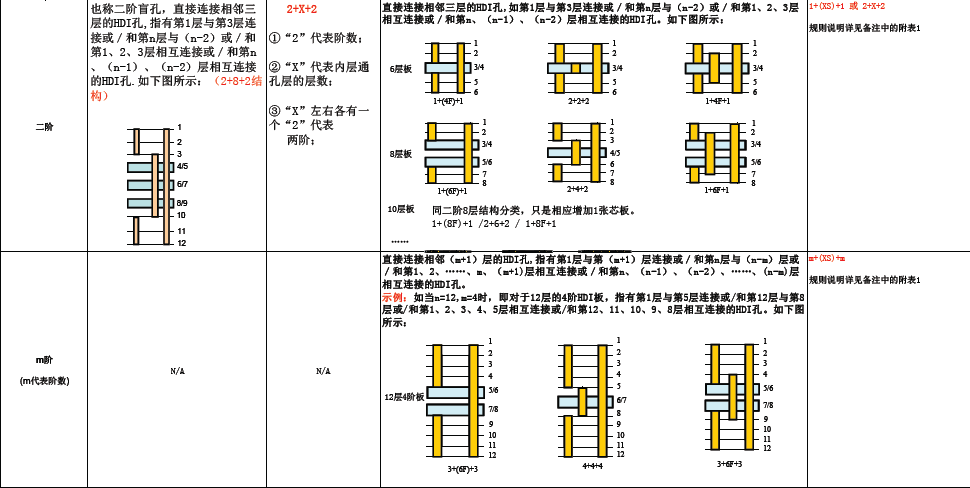

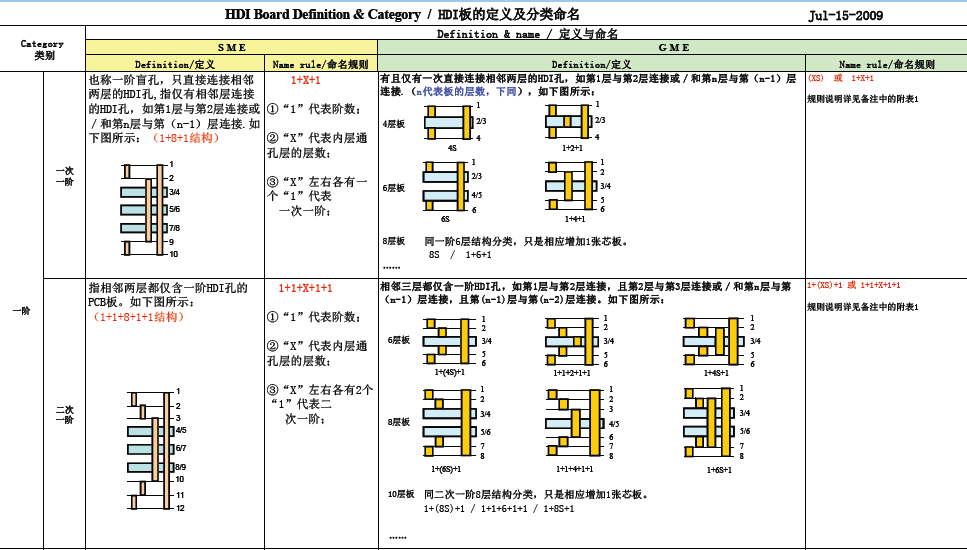

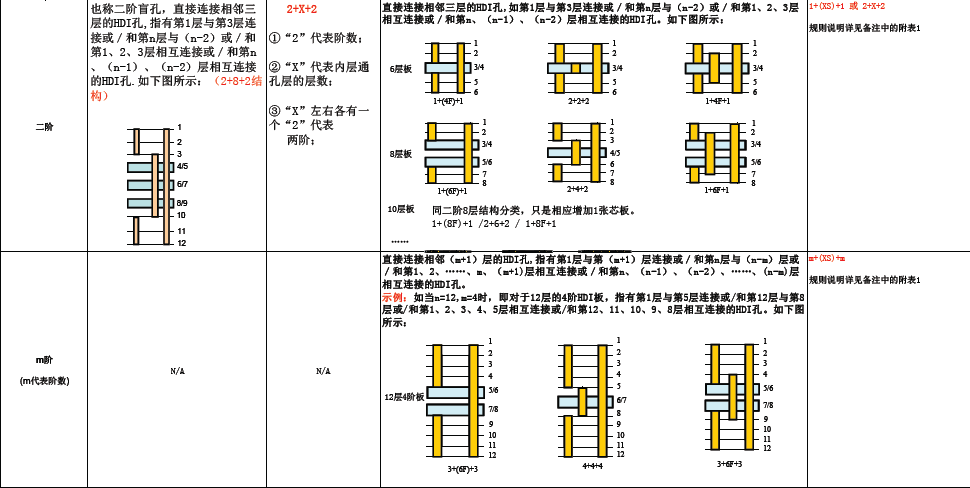

Akwai nau'ikan 6 daban-daban HDI PCB allon , daga saman zuwa saman ta ramuka, tare da ramukan da aka binne kuma ta ramuka, biyu ko fiye HDI yadudduka tare da ta ramuka, m substrates ba tare da lantarki dangane, ta yin amfani da Layer nau'i-nau'i Tsarin musanya tsarin na coreless tsarin da coreless tsarin yana amfani da Layer nau'i-nau'i.

Buga allon kewayawa tare da fasahar HDI Fasahar Kore Masu Amfani In-pad ta hanyar tsari yana goyan bayan ƙarin fasaha akan ƴan yadudduka, yana tabbatar da cewa girma ba koyaushe ya fi kyau ba.Tun daga ƙarshen 1980s, mun ga camcorders suna amfani da harsashi masu girman tawada, sun ragu don dacewa da tafin hannun ku.Kwamfuta ta wayar hannu da aiki a gida sun sami ƙarin fasahar ci gaba, suna sa kwamfutoci sauri da sauƙi, ba da damar masu amfani su yi aiki daga nesa daga ko'ina. Fasahar HDI shine babban dalilin waɗannan canje-canje.Samfurin yana da ƙarin ayyuka, nauyi mai sauƙi da ƙarami ƙarami.Kayan aiki na musamman, ƙananan sassa da ƙananan kayan aiki suna ba da damar samfuran lantarki su ragu cikin girman yayin haɓaka fasaha, inganci da sauri. Vias a cikin tsarin kushin Wahayi daga fasahar hawan dutse a ƙarshen 1980s ya tura iyakokin BGA, COB, da CSP zuwa ƙaramin murabba'in inci.In-pad ta hanyar tsari yana ba da damar sanya vias a saman kushin lebur.Ramin ramukan suna plated kuma a cika su da epoxy conductive ko mara daɗaɗɗa, sannan an rufe su kuma a yi musu farantin don sa su kusan ganuwa. Yana da sauƙi, amma yana ɗaukar matsakaicin ƙarin matakai takwas don kammala wannan tsari na musamman.Kayan aikin kwararru da masu fasaha masu horarwa suna da hankali sosai kan aikin don cimma cikakken ɓoye ta hanyar ramuka. Ta nau'in cikawa Akwai nau'ikan nau'ikan kayan cika ta hanyar rami daban-daban: epoxy mara ƙarfi, epoxy mai ɗaukar nauyi, cike da jan ƙarfe, cike da azurfa, da platin lantarki.Wannan zai sa a sayar da ramukan da aka binne a cikin fili gaba ɗaya zuwa ƙasar da aka saba.Hakowa, makafi ko binne ta hanyar mota, cikawa, sanyawa da ɓoyewa a ƙarƙashin pads ɗin SMT.Gudanar da irin wannan nau'in ta hanyar rami yana buƙatar kayan aiki na musamman kuma yana ɗaukar lokaci.Hawan hakowa da yawa da hakowa zurfin sarrafawa suna haɓaka lokacin sarrafawa. HDI mai tsada Kodayake girman wasu samfuran mabukaci ya ragu, ingancin har yanzu shine mafi mahimmancin mabukaci bayan farashi.Yin amfani da fasahar HDI a cikin ƙira, ana iya rage PCB-Layer ta rami-rami zuwa PCB fakitin fasahar micro-rami mai lamba 4 Layer HDI.Ƙarfin wayoyi na PCB HDI 4-Layer na gyare-gyare mai kyau na iya cimma ayyuka iri ɗaya ko mafi kyau a matsayin daidaitaccen PCB mai Layer 8. Kodayake tsarin microvia yana ƙara farashin HDI PCB, ƙira mai kyau da rage yawan yadudduka na iya rage farashin inci murabba'in na abu da kuma adadin yadudduka. Gina allunan HDI marasa al'ada Nasarar ƙera HDI PCB yana buƙatar kayan aiki na musamman da matakai, kamar hakowar Laser, toshewa, hoton Laser kai tsaye, da ci gaba da zagayowar lamination.Layin allo na HDI ya fi sirara, tazarar ta yi karami, zoben ya fi karfi, kuma ana amfani da siraran abu na musamman.Don samun nasarar samar da irin wannan jirgi, ana buƙatar ƙarin lokaci da babban zuba jari a cikin ayyukan masana'antu da kayan aiki. Fasaha hakowa Laser Hana ƙananan ƙananan ramukan yana ba da damar ƙarin dabaru don amfani da su a saman allon kewayawa.Yin amfani da katako mai diamita na microns 20 (mil 1), wannan katako mai tasiri na iya shiga karfe da gilashi don samar da kankana ta cikin ramuka.Sabbin samfura sun fito, kamar ƙananan laminates masu ƙarancin hasara da kayan gilashin iri ɗaya tare da ƙananan madaidaicin dielectric.Wadannan kayan suna da mafi girman juriya na zafi don taro mara gubar kuma suna ba da damar amfani da ƙananan ramuka. HDI allon lamination da kayan Babban fasahar multilayer yana ba masu ƙira damar ƙara ƙarin nau'i-nau'i nau'i-nau'i a jere don samar da PCB multilayer.Yin amfani da rawar jiki na Laser don ƙirƙirar ramuka a cikin Layer na ciki yana ba da damar plating, hoto, da etching kafin latsawa.Wannan tsari na ƙara ana kiransa tsarin gini.Masana'antar SBU tana amfani da tsattsauran ra'ayi don ba da damar ingantaccen sarrafa zafi

English en

English en