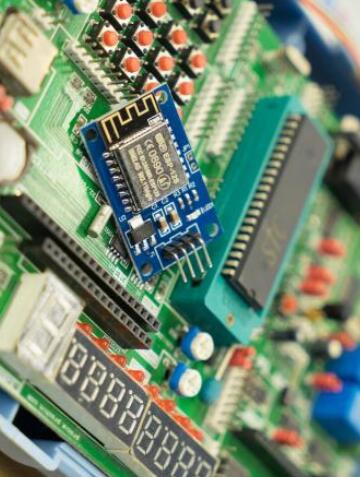

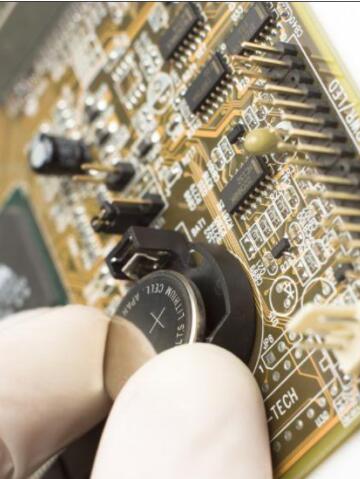

ABIS Circuits Co., Ltd established in 2006, Located in Shenzhen, our company has about 1100 workers and two PCB workshops with about 50000 square meters. Our products are mostly used in the field of Industrial Control, Telecommunication, Automotive products, Medical, Consumer, Security and others. Our perfect management, advanced equipment, and professional staffs are the keys for us to fight to win more market shares with other competitors.Customer satisfaction and support are what we have been strived for. Now we have passed ISO9001, ISO14001, UL, etc., With constant hard work of our staff and ongoing support from customers both home and abroad, we can provide up to 20 layers, Blind and buried Board, high-precision(Rogers), High TG, Alu-base and flexible boards to our customer with fast turn and high-quality level. Year Event 2006 ABIS Electronics Founded, and Set up the factory in Shenzhen 2008 Shenzhen Factory Put into Production and Passed the certification of America UL and ISO9001 2009 Shenzhen Factory got Canada UL.and Start to make 16 Layers in Volume 2010 Overseas Sales Department ABIS Circuits Co.,Ltd established 2010 Acquired the ISO14001 environmental management system certification 2012 The manufacturing equipment was updated and a batch of cutting-edge manufacturing equipment was imported from Sweden, France, the United States, Germany, and other countries 2015 We have a investment in our Subcontractor in Jiangxi, No of Employees 1200 with 5000 square meters, the plant monthly product capability reached to 40,000m2 2016 The team was refined, and all staff participated in the development training to create a wolf team 2017 Attend Expo Electronica 2017/ electronica India 2018 Attend Expo Electronica 2018/Electronica India 2019 Attend Expo Electronica 2019/ Electronica India

Englishen

Englishen