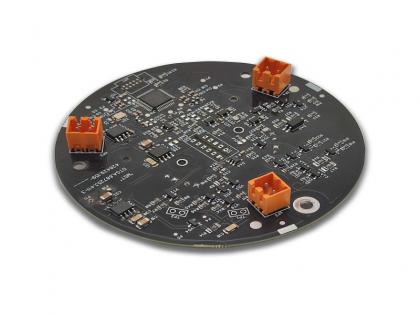

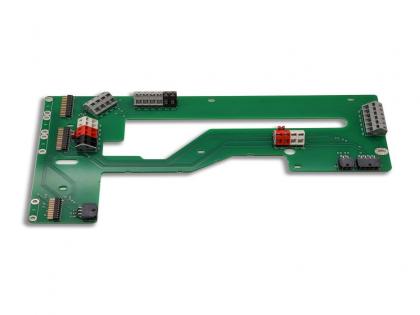

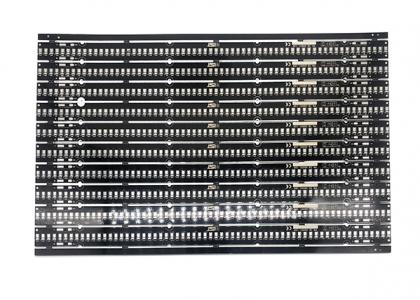

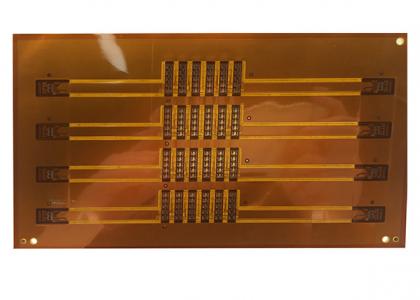

One-Stop PCB Assembly For Connector PCBA

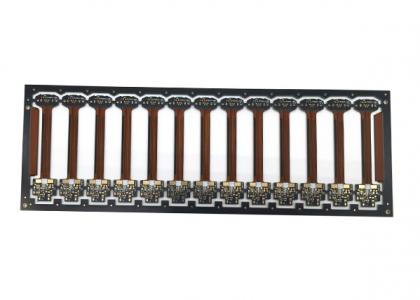

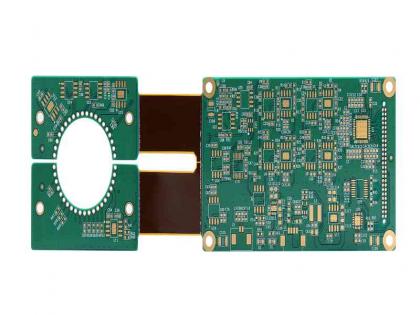

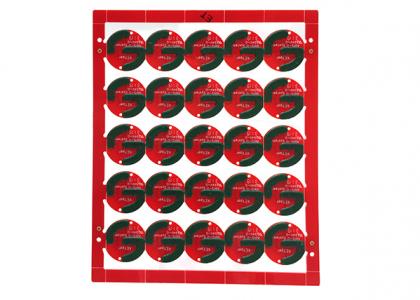

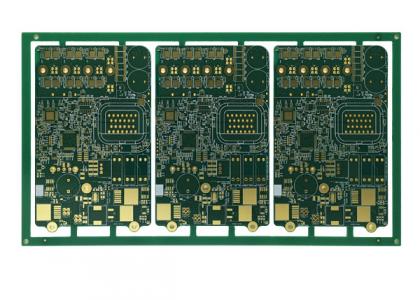

PCBA Projects Introduction ABIS CIRCUITS Company deliver services, not only products. We offer solutions, not only goods. From the PCB production, the components purchasing to the components assemble. Includes: PCB Custom PCB drawing / design according to your schematic diagram PCB manufacturing Component sourcing PCB Assemble PCBA 100% test Our Advantages High-end euipment-high speed Pick and Place Machines that can process about 25,000 SMD components per hour High efficient supply ability 60K Sqm monthly-Offers low volume and on-demand PCB production, also large-scale productions Professional engineering team-40 engineers and their own tooling house, strong at OEM. Offers two easy options: Custom and Standard-In-depth knowledge of IPC Class II and III Standards We provide a comprehensive turn-key EMS service to customers who want us to assemble the PCB into PCBA, including prototypes, NPI project, small and medium volume. We are also able to source all components for your PCB assembly project. Our engineers and sourcing team have rich experience in supply chain and EMS industry, with deep knowledges in SMT assembly allowing to resolve all the production issues. Our service is cost-effective, flexible, and reliable. We have satisfied customers across many industries including medical, industrial, automotive and consumer electronics. PCBA Capabilities 1 SMT assembly including BGA assembly 2 Accepted SMD chips: 0204, BGA, QFP, QFN, TSOP 3 Component height: 0.2-25mm 4 Min packing: 0204 5 Min distance among BGA : 0.25-2.0mm 6 Min BGA size: 0.1-0.63mm 7 Min QFP space: 0.35mm 8 Min assembly size: (X*Y): 50*30mm 9 Max assembly size: (X*Y): 350*550mm 10 Pick-placement precision: ±0.01mm 11 Placement capability: 0805, 0603, 0402 12 High pin count press fit available 13 SMT capacity per day: 80,000 points --Capability - SMT Lines 9(5 Yamaha,4KME) Capacity 52 million placements per month Max Board Size 457*356mm.(18”X14”) Min Component size 0201-54 sq.mm.(0.084 sq.inch),long connector,CSP,BGA,QFP Speed 0.15 sec/chip,0.7 sec/QFP -Capability - PTH Lines 2 Max board width 400 mm Type Dual wave Pbs status Lead-free line support Max temp 399 degree C Spray flux add-on Pre-heat 3 Production Processes Material Receiving → IQC → Stock → Material to SMT → SMT Line Loading → Solder Paste/Glue Printing → Chip Mount → Reflow → 100% Visual Inspection → Automated Optical Inspection (AOI) → SMT QC Sampling → SMT Stock → Material to PTH → PTH Line Loading → Plated Through Hole → Wave Soldering → Touch Up → 100% Visual Inspection → PTH QC Sampling → In-Circuit Test (ICT) → Final Assembly → Functional Test (FCT) → Packing → OQC Sampling → Shipping Quality Control AOI Testing Checks for solder paste Checks for components down to 0201 Checks for missing components, offset, incorrect parts, polarity X-Ray Inspection X-Ray provides high-resolution inspection of: BGAs/Micro BGAs/Chip scale packages /Bare boards In-Circuit Testing In-Circuit Testing is commonly used in conjunction with AOI minimizing functional defects caused by component problems. Power-up Test Advanced Function Test Flash Device Programming Functional testing IOC incoming inspection SPI solder paste inspection Online AOI inspection SMT first article inspection External assessment X-RAY-welding inspection BGA device rework QA inspection Anti-static warehousing and shipment Application Communication Units Industrial Control Medical Devices Automotive Units Network Devices Gateway Control Packaging & Delivery ABIS CIRCUITS Company is not only trying to give customers a good product, but also pay attention to offering a complete and safe package. Also, we prepare some personalized services for all the orders. -Common packaging: PCB: Sealed bag, Anti-static bags, Suitable carton. PCBA: Antistatic foam bags, Anti-static bags, Suitable carton. Customized Packaging: The carton outside will be printed the name of the customer address, mark, the customer needs to specify the destination and other information. -Delivery Tips: For small package, we advise to choose by Express or DDU service is the quickest way. For heavy package, the best solution is by sea transportation. Business Terms -Accepted Delivery Terms FOB, CIF, EXW, FCA, CPT, DDP, DDU, Express Delivery, DAF --Accepted Payment Currency USD, EUR, CNY. -Accepted Payment Type T/T, PayPal, Western Union. Quotation from ABIS To ensure an accurate quote, be sure to include the following information for your project: Complete GERBER files including the BOM list Quantities Turn time Panelization Requirements Materials Requirements Finish requirements Your custom quote will be delivered in just 2-24 hours, depending on the design complexity. Please keep us informed for any interests! ABIS cares every your ord

Englishen

Englishen